Vision for Industry 6.0: The Convergence of AI, Robotics and Human Ingenuity

No Doubts! The industrial world is undergoing another seismic transformation with industry 6.0. However, Industry 4.0 has helped companies to leverage the power of data, IoT, and automation to the manufacturing floor. While Industry 5.0 levied its focus on the synergy between humans and machines. Now, what’s next: Industry 6.0 will redefine the very fabric of how we think, design, and operate in industrial environments.

We know that the future will be marked with rapid technological acceleration and complex global challenges, Industry 6.0 is no longer related to upgrading machines. However, this industrial revolution will be creating a cohesive ecosystem with AI, robotics, automation, and human ingenuity collaborating to deliver intelligent manufacturing. This intelligent manufacturing will be sustainable, adaptive, and human-centered.

So, in this article, we’ll explore the following aspects:

- The vision of industry 6.0 with its key components

- The role of AI and robotics

- The impact of human machine collaboration to the next industrial revolution.

What does Industry 6.0 mean?

Absolutely! Industry 6.0 is marking the beginning of the next industrial revolution. This revolution is characterized by the following agendas:

- Seamless integration of AI

- Advanced robotics

- Human ingenuity.

Additionally, its primary focus is on intelligent manufacturing and human-machine collaboration. While the earlier industrial revolution emphasized automating tasks and enhanced efficiency. Hence, we can say that this revolution is not limited to machines doing the work. However, it’s about machines working with human interventions to design smarter and sustainable solutions for manufacturing and beyond.

Additionally, this revolution will define the integration of robotics and automation with human creativity, skills, and expertise. Therefore, this approach has helped with several new opportunities or possibilities, like enhancing safety, better operation efficiency, customization, and responsiveness.

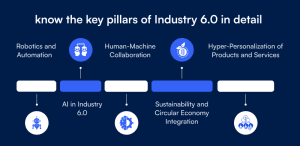

Now, it’s the time to understand or know the key pillars of Industry 6.0 in detail:

1. Robotics and Automation: The Backbone of Industry 6.0:

If you think Robotics and Automation are an integral part of industrial progress, then you are somehow wrong. The introduction of Industry 6.0 has marked the evolution of robotics. Today! automation can handle repetitive tasks to enhance business speed and efficiency. However, the integration of AI to robotics can make this technology to be more adaptive and capable of responding to complex variables.

Eventually, the rise of collaborative robots or cobots is somehow marking the latest trends of robotics within Industry 6.0. These cobots are designed to work side by side with human workers. This states that these robots can learn from human actions, understand context, and adjust their behaviors.

2. AI in Industry 6.0: The Cognitive Engine of Industrial Innovation:

Acting as catalyst, AI is helping businesses to drive transformation towards Industry 6.0. The concept significantly benefits attaining cognitive capabilities to industrial systems. This includes several tasks like learning from vast amounts of data, making predictions, and making decisions autonomously or in collaboration with humans.

Keeping industrial innovation as focused, there are several AI-driven technologies like predictive analytics, deep learning or data science consulting services that are being used to attain following aspects:

- Optimize Production processes

- Predict machine failures

- Enhance supply chain management

For instance: Predictive Analytics can forecast demand fluctuations that ensures companies to adjust their production schedules or inventories in real-time. These analytics can significantly help to reduce waste, enhance operational efficiency, and optimal allocation of resources.

3. Human-Machine Collaboration: Bridging the Gap Between Execution and Innovation:

Undoubtedly! AI and robotics are powerful technologies. However, businesses still require human input. Unlike the previous industrial revolution, Industry 6.0 tends to shift its focus to human-machine collaboration, i.e., human bringing creativity, intuitions, and critical thinking while machines provide computational power, speed, and accuracy. This collaboration significantly highlights the next level of innovation with productivity.

This human-machine collaboration is crucial in decision-making aspects, especially when complex or context-dependent judgements are requisites. AI can help with data-driven insights; however, it is humans responsible for interpretation of insights.

Therefore, Industry 6.0 helps workers to tackle meaningful and impactful tasks, instead of being obstacles with repetitive tasks.

4. Sustainability and Circular Economy Integration:

Another pillar associated with Industry 6.0 is green manufacturing, energy efficiency, and sustainable industrial ecosystems. To attain its objective of sustainability and circular economy, Industry 6.0 can help will following aspects:

- The involvement of real-time carbon tracking in Smart factories can help with waste minimization and closed loop supply-chains.

- AI in Industry 6.0 will model and simulate environmental impacts. This will help businesses with greener choices.

- Also, decentralized manufacturing based on 3D printing or modular designs will help in reducing the complexities of logistics or environmental impacts.

Therefore, Industry 6.0 becomes a force for ecological and economic balance.

5. Hyper-Personalization of Products and Services:

Industry 6.0 will help business with real-time data analytics and intelligent manufacturing. These two opportunities will provide a shift from mass production to mass personalization. Using Industry 6.0, following aspects can be observed:

- Machines will rely on-the-fly to change user preferences.

- AI will significantly enhance predictive demand to ensure planning and automatic customization.

- Product lines will evolve continuously. This will highlight the latest trends with feedback and behavior patterns.

This agility will ensure relevance with customer satisfactions to attain experience-driven markets.

What are the Benefits of Industry 6.0?

Companies or businesses adopting Industry 6.0 principles can enjoy several benefits, irrespective of the industry or environment they are dealing with. So, the list of benefits associated with industry 6.0 are as follows:

- Better Productivity using adaptive automation

- Resilient operations to avoid global disruptions

- Higher employee satisfactions with augmented roles or safer workplaces

- Smarter products or services personalized based on user’s expectations

- Greener footprints through real-time environment optimization

- Quicker innovation cycles via autonomous R&D systems

Ultimately, Industry 6.0 enables organizations to compete not just on cost or efficiency, but on value, ethics, and purpose.

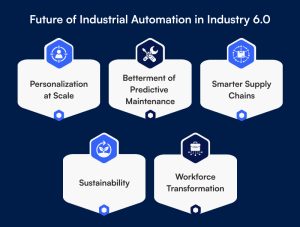

What is the Future of Industrial Automation in Industry 6.0?

The uncertain rise of Industry 6.0 is essentially marking the turning point in industrial automation. With such new era, businesses can surely observe the following shifts:

1. Personalization at Scale:

AI And Robotics has made it possible to businesses to enable mass production with added customization that was impossible earlier. In an intelligent manufacturing environment, AI can help companies to design products to favor customer’s specifications without compromising efficiency.

2. Betterment of Predictive Maintenance:

Using AI with predictive analytics ensures manufacturers to maintain their machinery before occurrence of any failure to reduce downtime or extends equipment lifespans. This will revolutionize industries with strong reliance on complex machinery.

3. Smarter Supply Chains:

This industrial revolution will usher in smarter or more responsive supply chains. Therefore, companies can track products or material in real-time, optimize routes, and forecast demand by integrating AI with Robotics and IoT.

4. Sustainability:

Nowadays, Industries looking and striving for greener practices, AI can be beneficial for optimization of energy consumption, reducing waste, or streamlining production processes. These aspects will further contribute to more sustainable manufacturing systems.

5. Workforce Transformation:

Automation is clearly taking over routine tasks. Thus, human workers are focusing on higher-value activities that require critical thinking, creativity, or emotional intelligence. This will also require a shift in workforce skills, with a greater emphasis on collaboration with AI and robotics.

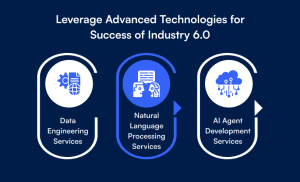

How to Leverage Advanced Technologies for Success of Industry 6.0?

Industry 6.0 tends to strongly rely on integrating cutting-edge technologies. So, here’s how some of the emerging technologies play a critical role:

1. Data Engineering Services:

AI systems are truly based and thrive on data. Thus, companies require robust data engineering services to collect, process, and organize data effectively. So, with lack of proper data management, AI systems fail to deliver accurate predictions or optimizations.

2. Natural Language Processing Services (NLP):

NLP helps machines to interact or understand human instructions naturally. Additionally, NLP can also enable machines to interpret and respond to human-based queries in real-time.

3. AI Agent Development Services:

AI Agents will be working as VAs. These will help workers to navigate through complex systems, handle repetitive tasks, or interact with machines and humans in an intuitive way.

Conclusion:

Undoubtedly! Being a next frontier industrial resolution, Industry 6.0 defines a profound shift in how we view industrial systems. Therefore, by leveraging AI, robotics, and human ingenuity, businesses or companies can unlock new levels of productivity, personalization, and sustainability. Therefore, this new gen era promises help business with following results:

- Better industrial operations

- Attain innovative future

- Betterment of role of human workers

- Creation of collaborative future

As industries prepare for the future of industrial automation, those who invest in AI-powered tools, predictive analytics solutions, data science consulting services, and human-machine collaboration will lead the way in shaping the next generation of industrial processes.

The future of Industry 6.0 is here, and it’s a future where technology and human expertise work hand in hand to drive smarter, more sustainable, and more innovative industrial solutions.

Is your business ready for the convergence of AI, automation, and human creativity? Let us be your partner to design your path to the factory of the future. Let’s build smarter, together.